Reducing cryogenic costs

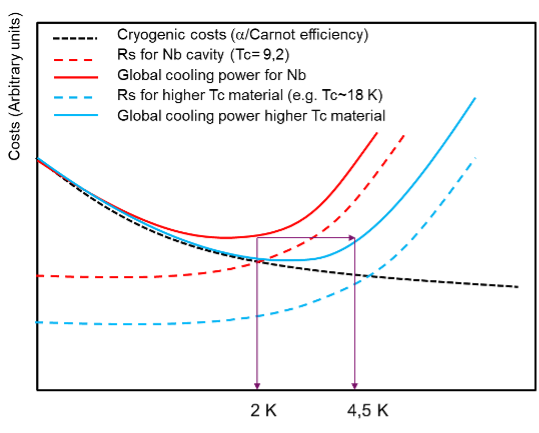

Working at liquid helium (≥4.5 K) rather than superfluid helium at 2K is a way to decrease cryogenic investment by a factor 30-40%. The cryogenic operation cost is then divided by another factor 3. This is already the case at low frequency, for circular machine which do not require high accelerating gradient like LHC. Niobium films with properties closer to bulk Nb are already on their way, but still far from being applied on a production scale. Better performances are expected for more ambitious machines[AC1] . The only way to reach such high performances is to use higherTc superconductors, which present their own challenges: most of them are brittle and can only be deposited as films. They are compounds and need to be prepared with an accurate composition and structure. Depositing higher Tc material on copper cavities will require a few more years of R&D, after completing the undergoing optimization conducted on samples and small cavities. Several different compounds need to be explored in parallel to determine which one will be best fitted to larger production requirements. Cavities with superconducting films deposited on copper, working at 4.5 K with moderate accelerating gradients will be probably the first step to be reached.

Working at higher temperature opens the way to cooling with cryocoolers, ending the necessity for large cryogenic plants and their huge helium inventory.

Enhancing accelerating gradients

Thin films are also liable to lead to an increase in accelerating gradients, leading to more compact machines and reducing RF investments and operation costs. Higher accelerating gradients will more likely emerge from multilayers SIS structures, which demands that thicker films deposition is first fully mastered. The achievement of deposition of multilayers with similar properties as bulk Nb, is foreseeable in the next 2-3 years at the prototype stage. Further improving performances will require a substantial investment than what is the case nowadays.

Reproducibility, cost, industrial manufacturing

Mastering the deposition of superconducting thin films on copper cavity able to operate at 4.5 K will have tremendous effects in reducing fabrication and investment costs. In this venture, the focus is not only on Superconducting RF performances, but also on the ease and the yield of manufacture, and the sensitivity to several operation steps: tuning vs brittleness, composition and poor magnetic field expulsion at the transition, etc…