To speed up R&D, labs have prioritized needed investments within the next 5 years on the following identified items :

- Push forward the development and validation of large/medium grain material

- Obtain operational CW cryomodule at gradients > 20 MV/m

- Develop new vendors of LG/MG ingots to allow mass production

- Continue R&D on vacuum heat treatment

- Push further investigation of the annealing technique (mid-T baking, 2 steps …)

- Demonstrate improvements and applicability of these advanced heat treatments at frequencies other than 1.3 GHz

- Improvement of surface treatment with surface polishing and characterization techniques: standard techniques (EP, BCP), new techniques (EPP, MP, etc.) and doping

- Develop new infrastructures for large cavities (multi-cells, low beta …): cold EP, rotational BCP

- Investigate and develop doping and infusion

- Investigate, identify and optimize polishing techniques compatible with SRF requirements and industrialization

- Develop human-robot collaboration (robotisation/cobotisation) for surface processing and cleaning of SRF components

- Obtain operational robot in clean rooms and demonstrate improved cleanliness

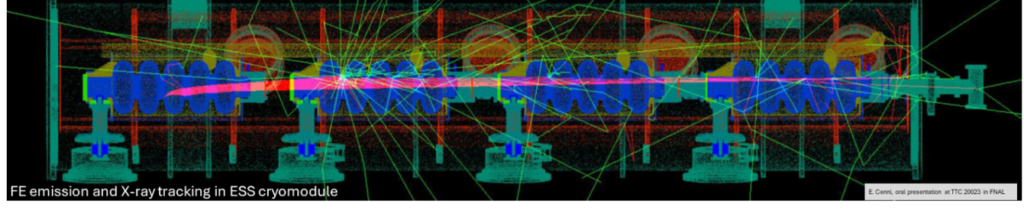

- Pursue R&D effort on X-rays diagnostics capabilities

- Show improved efficiency and yield of surface preparation

- Intensify R&D on field emission mitigation/in-situ recovery techniques (dry-ice cleaning, plasma processing)

- Deployment and show efficiency of these techniques for accelerator in operation